We combine advanced CNC control with experienced metalworkers to provide results you can rely on. Our tube laser cutting delivers tolerances as tight as ±0.1 mm, which reduces secondary finishing, minimizes scrap, and ensures consistent assembly fit for welded assemblies, railings, frames and complex architectural elements.

- Precision & repeatability: ideal for production runs and one-off custom parts.

- Complex geometry: slots, ports, mitres, angled cuts and curved patterns for decorative panels and structural components.

- Material versatility: steel, stainless steel, aluminum and common alloys.

- Turnkey workflow: CAD/CAM programming → tube laser cutting → welding → surface prep → powder coating.

Capabilities & services we provide

Our shop couples tube laser cutting with complementary fabrication services so you get finished components — not just bare cut parts. Core capabilities include:

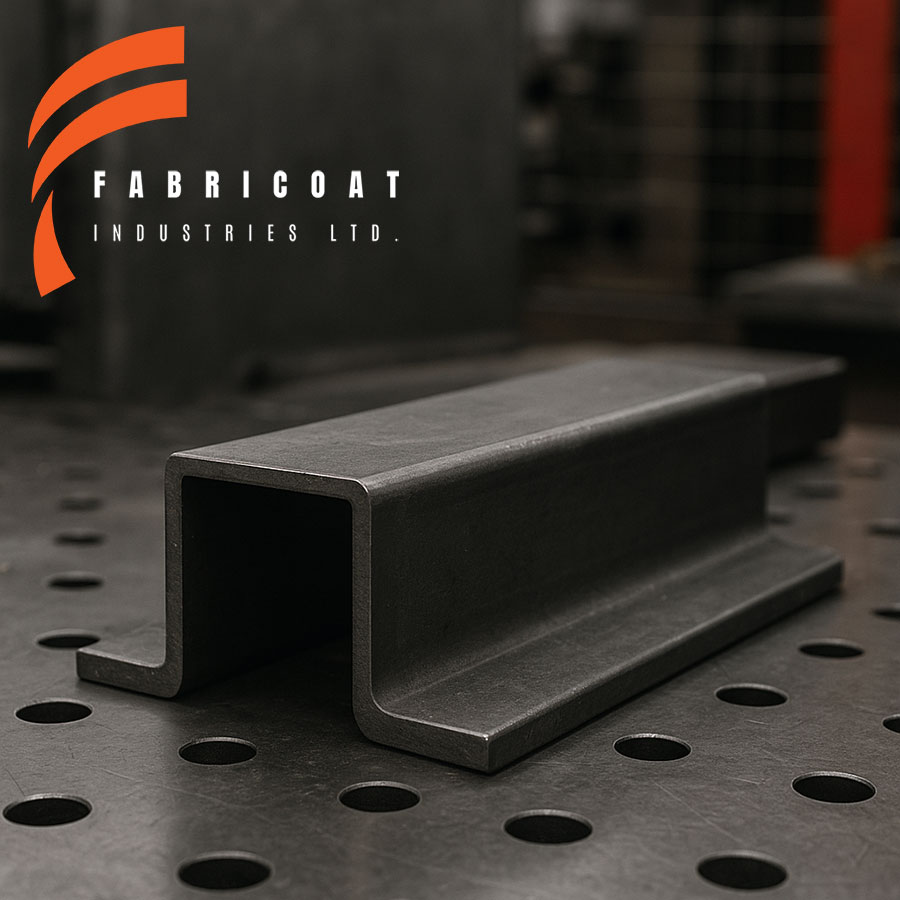

- Tube laser cutting for round, square and rectangular tube profiles (holes, slots, miters, notches).

- CNC laser cutting for sheet and plate to produce industrial metal parts and decorative panels.

- Precision sheet metal bending and forming for assemblies.

- Welding services (MIG, TIG, Stick, Spot) for structural and cosmetic joins — see our Welding Services page for details.

- Sandblasting and surface preparation followed by industrial and custom powder coating.

Decorative & architectural applications

Beyond heavy industry, tube laser cutting is widely used for decorative metalwork and architectural features. Our team produces:

- Custom metal wall art and laser-cut decorative panels for interior and exterior installations.

- Modern railing systems, cable rail components, and custom stair balustrades (powder coating available).

- Floating and spiral stair elements fabricated to spec and finished for installation.

Explore design inspiration and fabrication methods at The Fabricator to better understand how metalwork is used in modern architecture.

Industries we serve

We support a wide range of sectors including structural steel fabrication contractors, agricultural equipment manufacturers, mining and marine suppliers, truck and trailer fabricators, and specialty architectural firms that require aesthetic metal components. Our Maple Ridge facility supplies finished parts to customers across Vancouver and the Lower Mainland.

Local workmanship & easy project delivery

As a local metal fabrication company in Maple Ridge, we focus on reliability and communication. Typical project workflow:

- Design review and CAD/CAM programming

- Tube laser cutting and quality inspection

- Welding and assembly where required

- Surface preparation (sandblasting) and industrial powder coating options

- Final QA and delivery or coordination with your installer

Learn more about our end-to-end finishing options on our Powder Coating Services page.

Request a quote

If you need an accurate quote for tube laser cutting services, custom railing fabrication, or powder coated architectural components, we provide timely estimates and technical guidance. Use our contact page or click the button below to request a free project consultation and quote.