Eco-Innovation in Metal Fabrication and Powder Coating

Eco-Innovation in Metal Fabrication and Powder Coating At Fabricoat, we are committed to eco-innovation in every aspect of our metal

Eco-Innovation in Metal Fabrication and Powder Coating At Fabricoat, we are committed to eco-innovation in every aspect of our metal

Fabricoat specializes in industrial metal fabrication, CNC laser cutting, and custom powder coating in Maple Ridge, BC. Quality-built solutions for every industry.

The Ultimate Guide to Powder Coating Cost per Square Foot When planning a metal fabrication project, one of the most

Industrial Fabrication Quotes: What Affects Price When requesting an industrial fabrication quote, many clients wonder what determines the price of

The Ultimate Guide to Custom Metal Railing: 5 Key Benefits for Modern Homes Transform Your Home with Stylish Railings Searching

Expert Welding Services in Maple Ridge & Vancouver – MIG, TIG, Stick & Spot Welding Welding Services in Maple Ridge

Fabricoat specializes in industrial metal fabrication, CNC laser cutting, and custom powder coating in Maple Ridge, BC. Quality-built solutions for every industry.

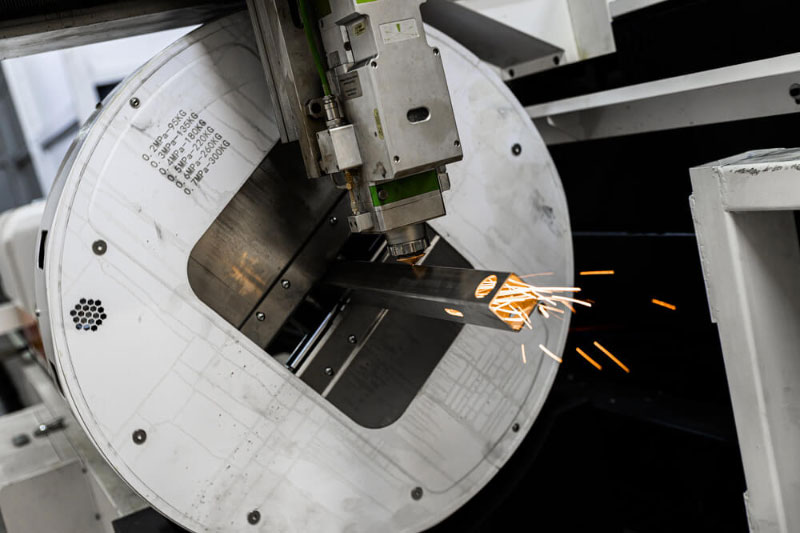

Ionized gas melts through conductive plate at blazing speeds. Delivers crisp edges on steel, stainless, and aluminum.

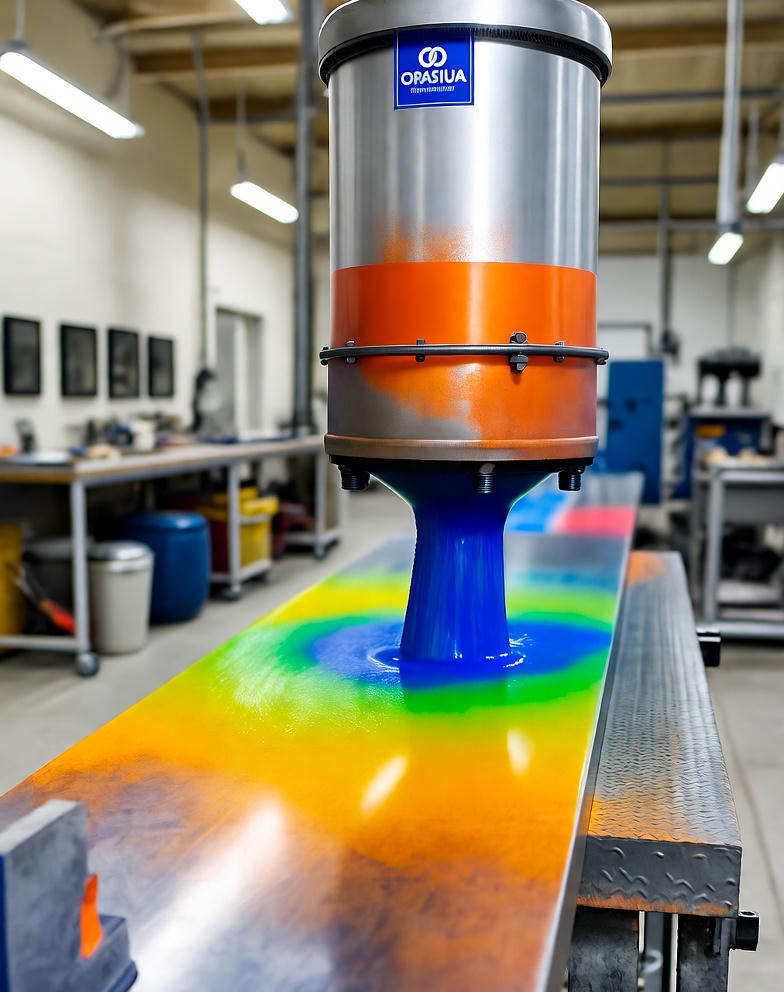

At Fabricoat, we provide professional Powder Coating Services in Maple Ridge, Vancouver, and across the Lower Mainland. Our team specializes in durable, eco-friendly finishes that protect and enhance metal components of all kinds. From custom metal fabrication and industrial metal parts to custom railings, stairs, truck and trailer fabrication, and decorative metal panels, our powder coating process ensures a long-lasting finish that resists chipping, corrosion, and fading.

CNC machining services utilize computer-controlled mills, lathes, and routers to transform raw metal or plastic into precision parts. This process ensures micron-level accuracy, flawless repeatability, and consistent quality, making it ideal for custom metal fabrication, industrial components, and intricate designs.

Our sandblasting services use high-velocity abrasive media to efficiently remove rust, old coatings, and surface contaminants from metal, concrete, or wood. This process creates a perfectly keyed surface ideal for powder coating services or other finishing applications, enhancing corrosion resistance, paint adhesion, and the overall lifespan of industrial metal parts. As part of our comprehensive metal fabrication services, sandblasting ensures consistent, uniform results for both custom and large-scale projects.

Our flame cutting services (oxy-fuel) efficiently slice carbon-steel plates up to 8″ thick using a focused oxygen jet that burns through the metal, delivering square, clean edges at production speed and low cost. Meanwhile, our plasma cutting services utilize high-definition ionized gas to melt and remove material, providing near-laser precision on stainless steel, aluminum, or mild steel up to 1½” thick. Both methods handle complex contours in a single pass, making them ideal for custom metal fabrication and industrial metal parts in Maple Ridge, Vancouver, and the Lower Mainland.

A laser beam slices metal or acrylic with hairline kerfs and no burrs. Ideal for intricate patterns and minimal cleanup.

They are a base material in applications that do not require any formability beyond minimal bending and/or roll-forming.