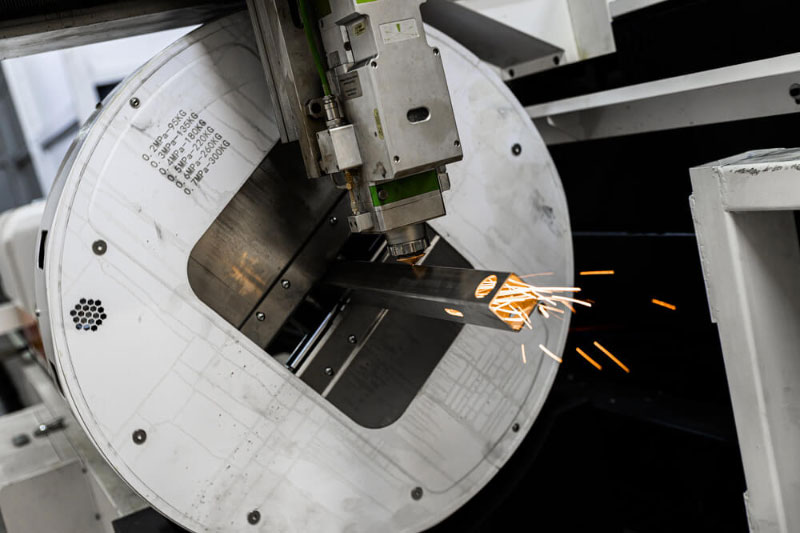

Precision Cutting

Achieves tight tolerances and smooth edges.

Maintains dimensional accuracy even on thin-walled tubing.

Material Versatility

Suitable for metals including steel, stainless steel, aluminum, brass, and copper.

Compatible with plastic tubing for industrial and consumer applications.

Complex Geometries

Cut slots, holes, notches, and patterns directly into tubes.

Create intricate joints and connections without secondary machining.

Efficiency & Repeatability

Faster than traditional sawing or mechanical cutting.

CNC-controlled lasers ensure each cut is consistent, part after part.

No deformation: Protects tube walls from crushing or heat distortion.

Reduced secondary processing: Minimal need for deburring or refinishing.

Design freedom: Allows innovative structures, assemblies, and patterns.

Cost efficiency: Less material waste, faster turnaround, and scalable production.

Automotive exhaust systems, chassis components, and frames

Aerospace tubing and lightweight structural assemblies

Architectural and decorative tubing (railings, facades, furniture)

Medical device components requiring small-diameter precision cuts

Industrial equipment and machine frameworks