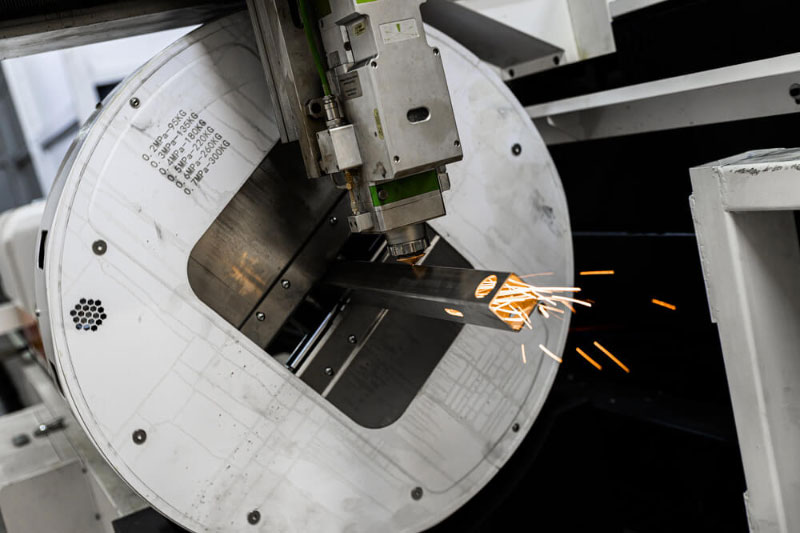

At Fabricoat, we specialize in high-precision Laser Tube Cutting Services, serving Maple Ridge, Vancouver, and the Lower Mainland. Our state-of-the-art equipment, advanced CNC technology, and experienced technicians ensure accurate and clean cuts for a wide variety of materials, including steel, stainless steel, aluminum, and more. Whether your project involves custom metal fabrication, structural components, or industrial applications, our laser tube cutting solutions provide unmatched precision, efficiency, and reliability.

Why Choose Our Laser Tube Cutting Services?

- High Precision: Our advanced laser technology enables tight tolerances and complex geometries for intricate industrial and decorative designs.

- Versatility: Capable of cutting tubes of various sizes and materials, our services adapt to your unique project requirements.

- Efficiency: Fast turnaround times without compromising quality, helping keep your project on schedule and within budget.

- Local Expertise: Serving Maple Ridge, Vancouver, and the Lower Mainland, we understand the specific needs of local industries and businesses.

Applications of Laser Tube Cutting

Our laser tube cutting services are ideal for a wide range of applications:

- Custom Metal Fabrication: Perfect for creating intricate components, modern metal artwork, decorative panels, and architectural designs.

- Structural Components: Produce precise parts for construction, industrial machinery, automotive, aerospace, and marine fabrication projects.

- Industrial Applications: Manufacture durable and accurate components for manufacturing equipment, heavy-duty metal parts, and large-scale production runs.

Flame, Plasma, and Laser Precision

In addition to laser tube cutting, Fabricoat offers complementary services such as flame cutting for carbon steel up to 8″ thick and plasma cutting for stainless steel, aluminum, and mild steel up to 1½” thick. These methods, combined with our CNC laser cutting capabilities, allow us to handle complex contours in a single pass, ensuring precision and repeatability for industrial metal parts and custom metal fabrication projects. Learn more about precision cutting standards at Modern Machine Shop.

Serving Maple Ridge, Vancouver & the Lower Mainland

As a trusted metal fabrication company near me, Fabricoat is committed to delivering high-quality laser tube cutting solutions. Our team collaborates closely with clients to understand project specifications, recommend optimal materials, and achieve consistent, precise results. We also integrate powder coating services for finishing, providing durable, corrosion-resistant surfaces that extend the life of your metal components.

Request a Free Quote

Ready to get started? Contact us today for a free quote on our laser tube cutting services. Let Fabricoat bring your custom metal fabrication project to life with precision, efficiency, and professional expertise.